3D boolean operations are essential for creating complex shapes and forms that would be difficult or time-consuming to model from scratch using traditional modeling techniques.

3D Boolean operations are crucial in 3D modeling and manufacturing, streamlining the creation of complex models by allowing for efficient combination and subtraction of shapes.

Overall, 3D boolean operations facilitate the design of intricate shapes, playing a key role in modern manufacturing by improving output quality and efficiency.

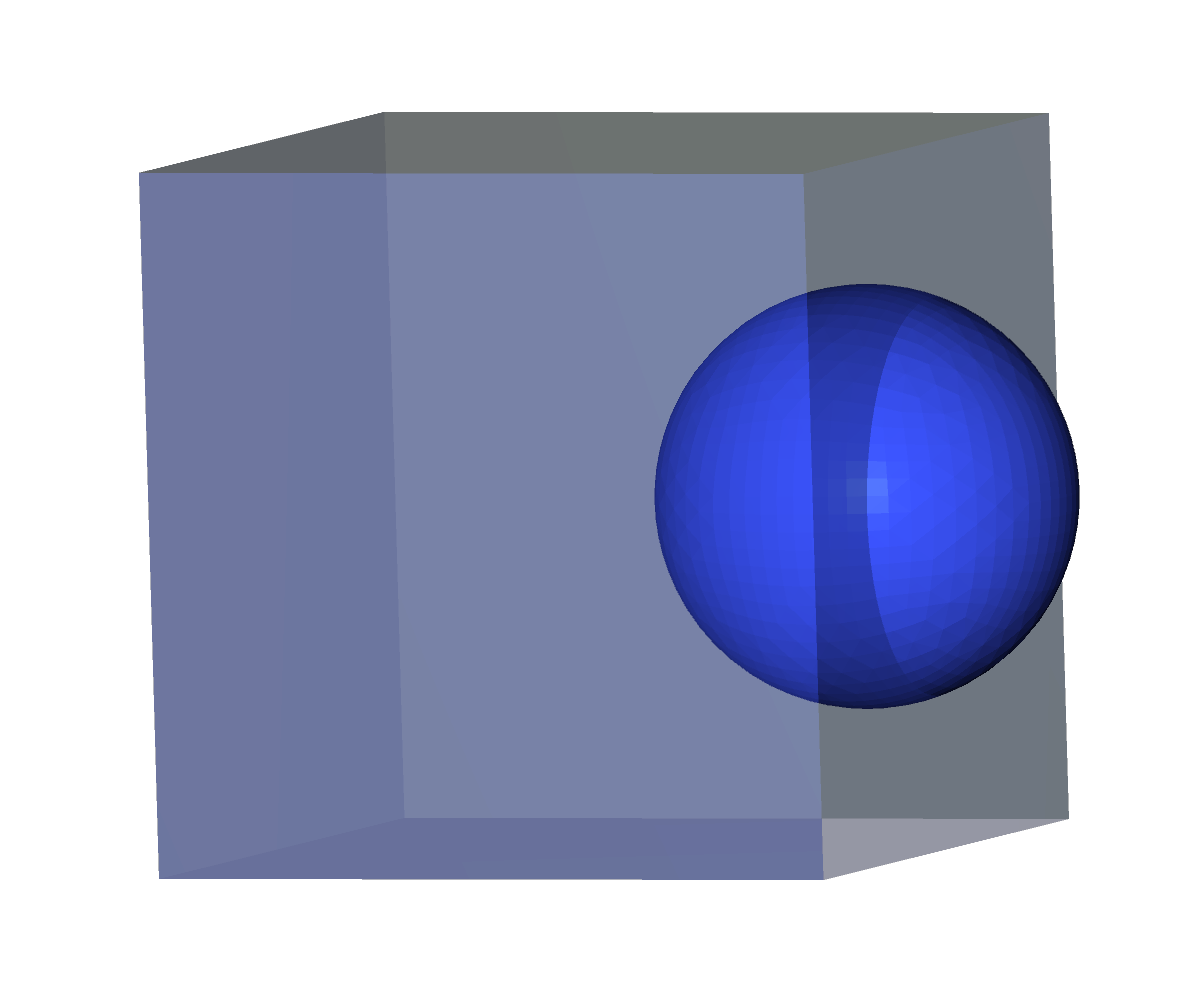

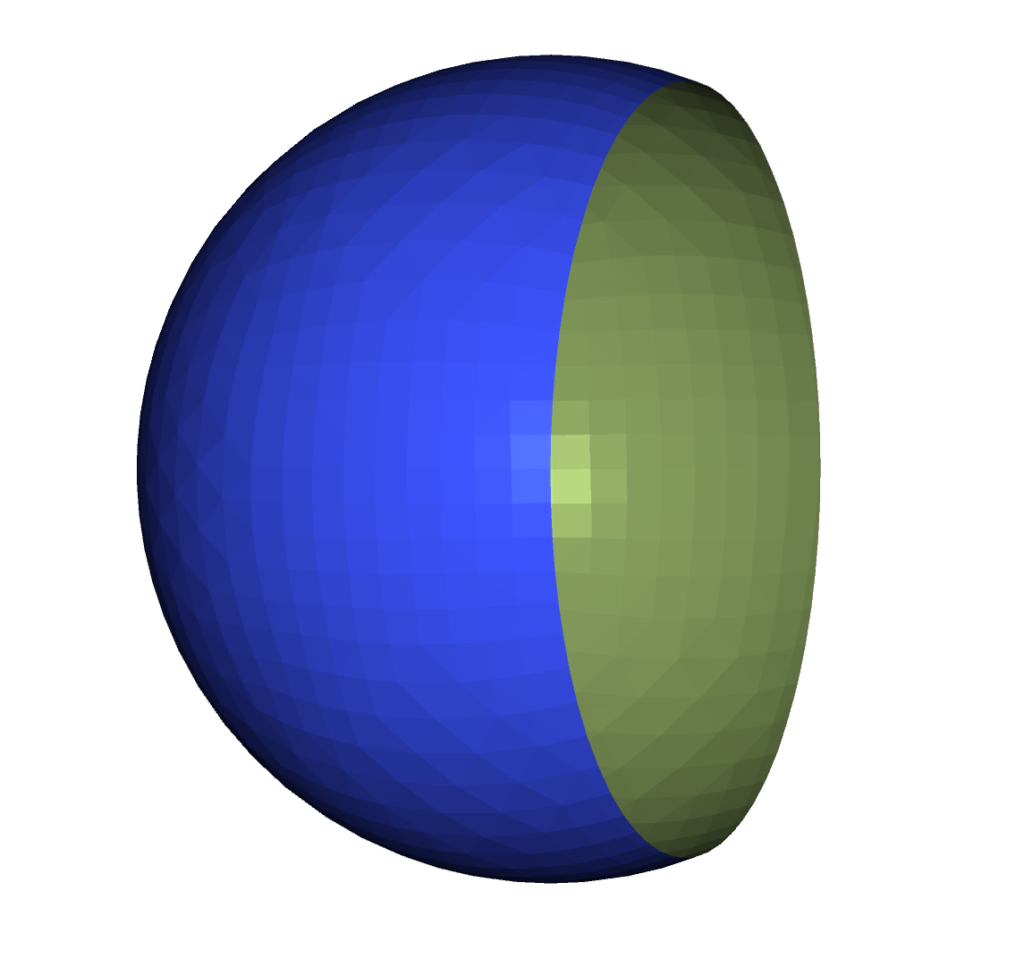

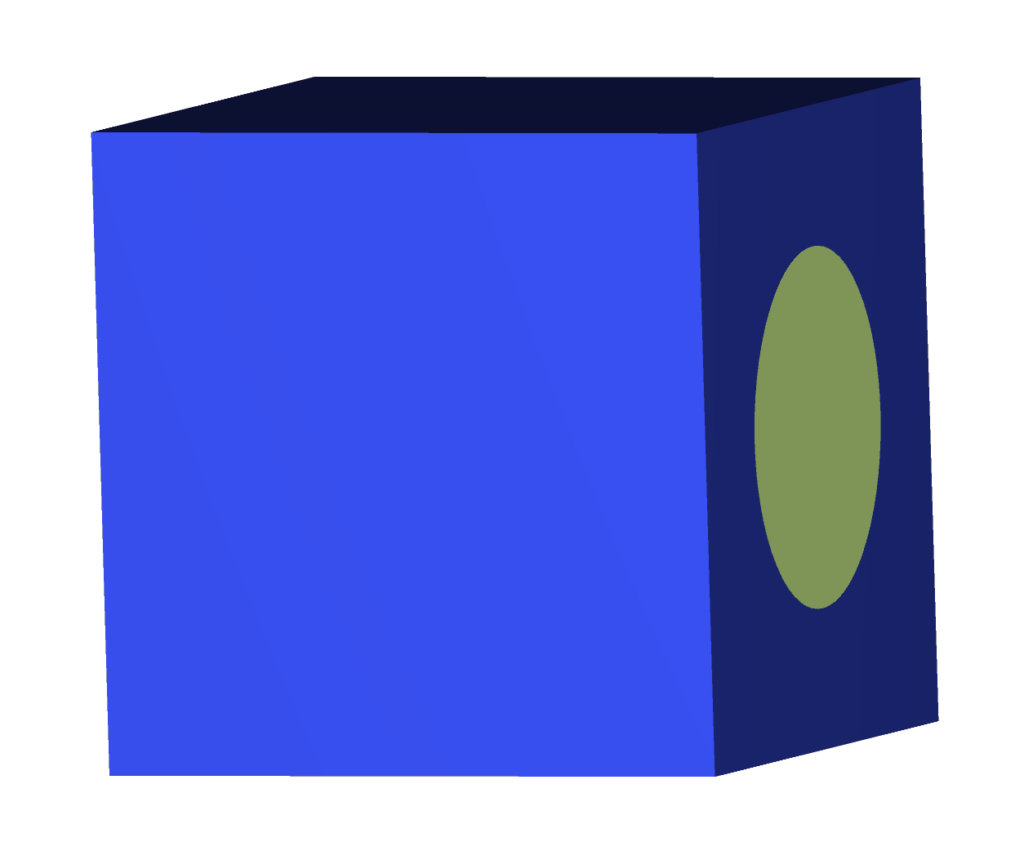

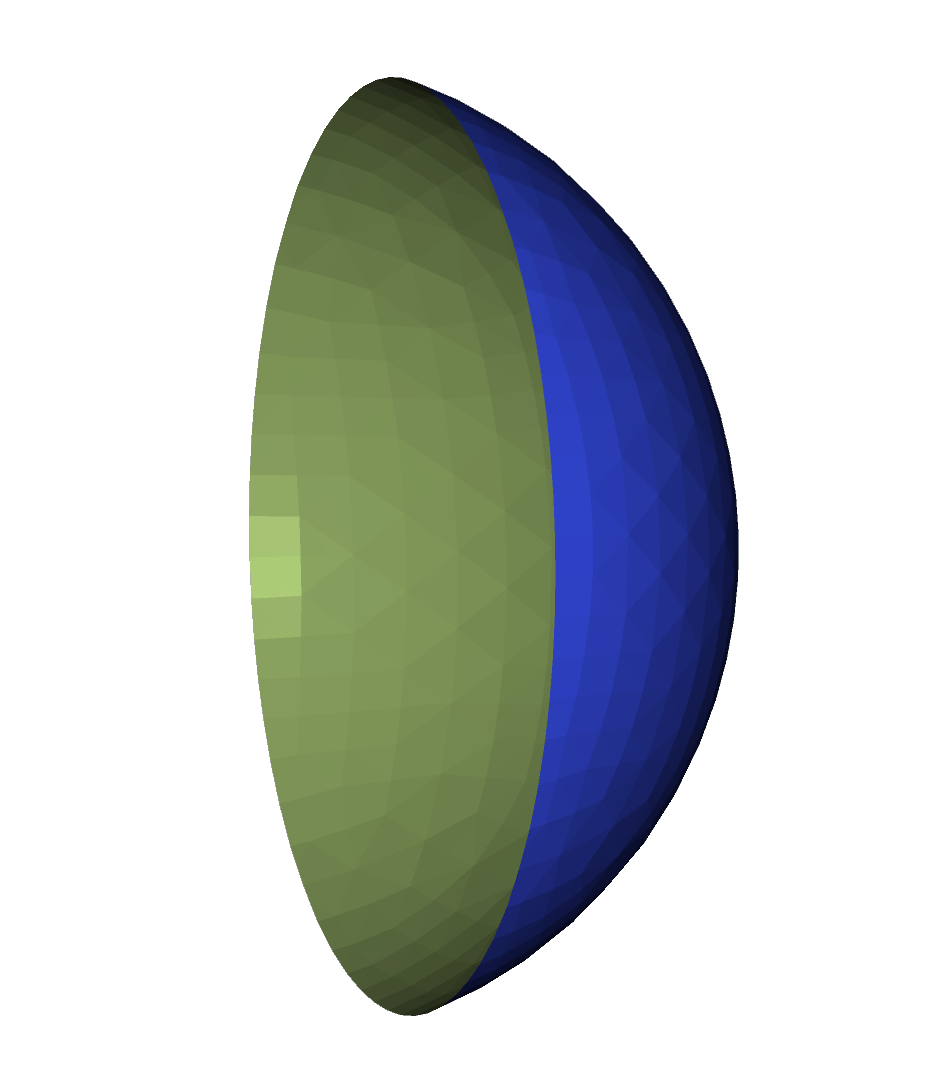

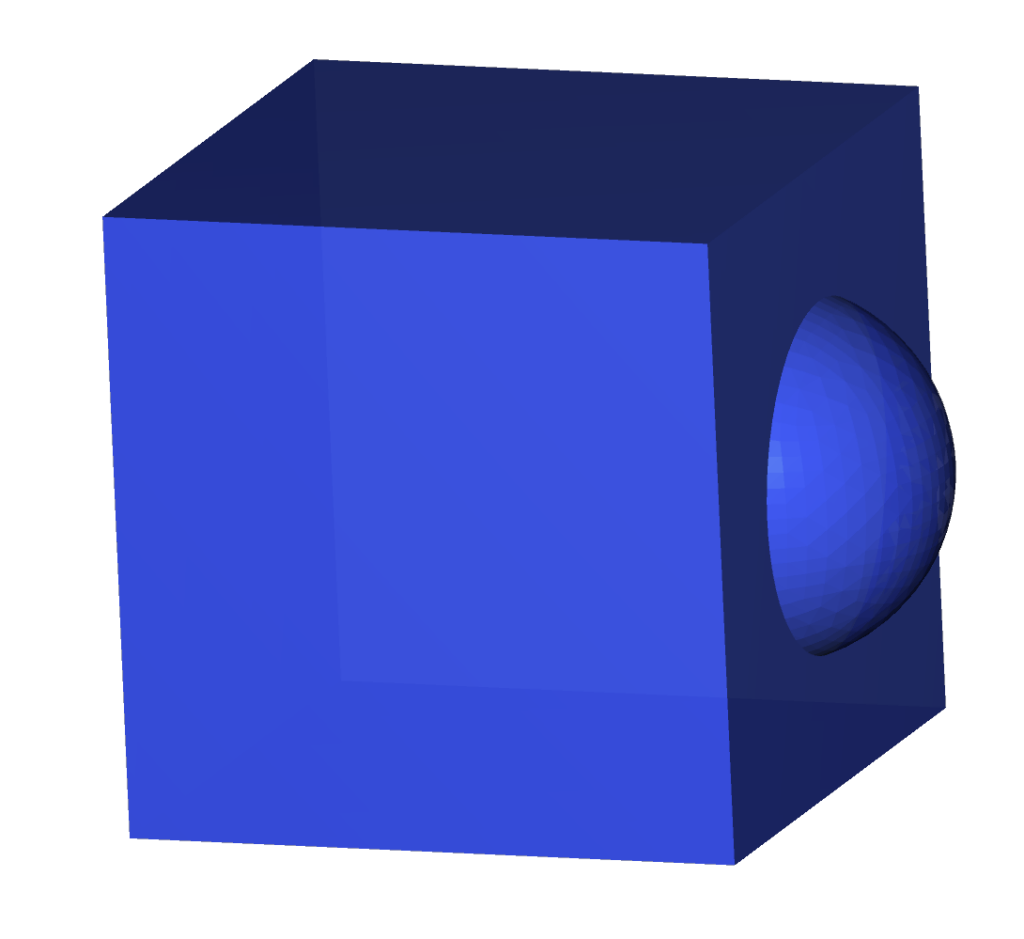

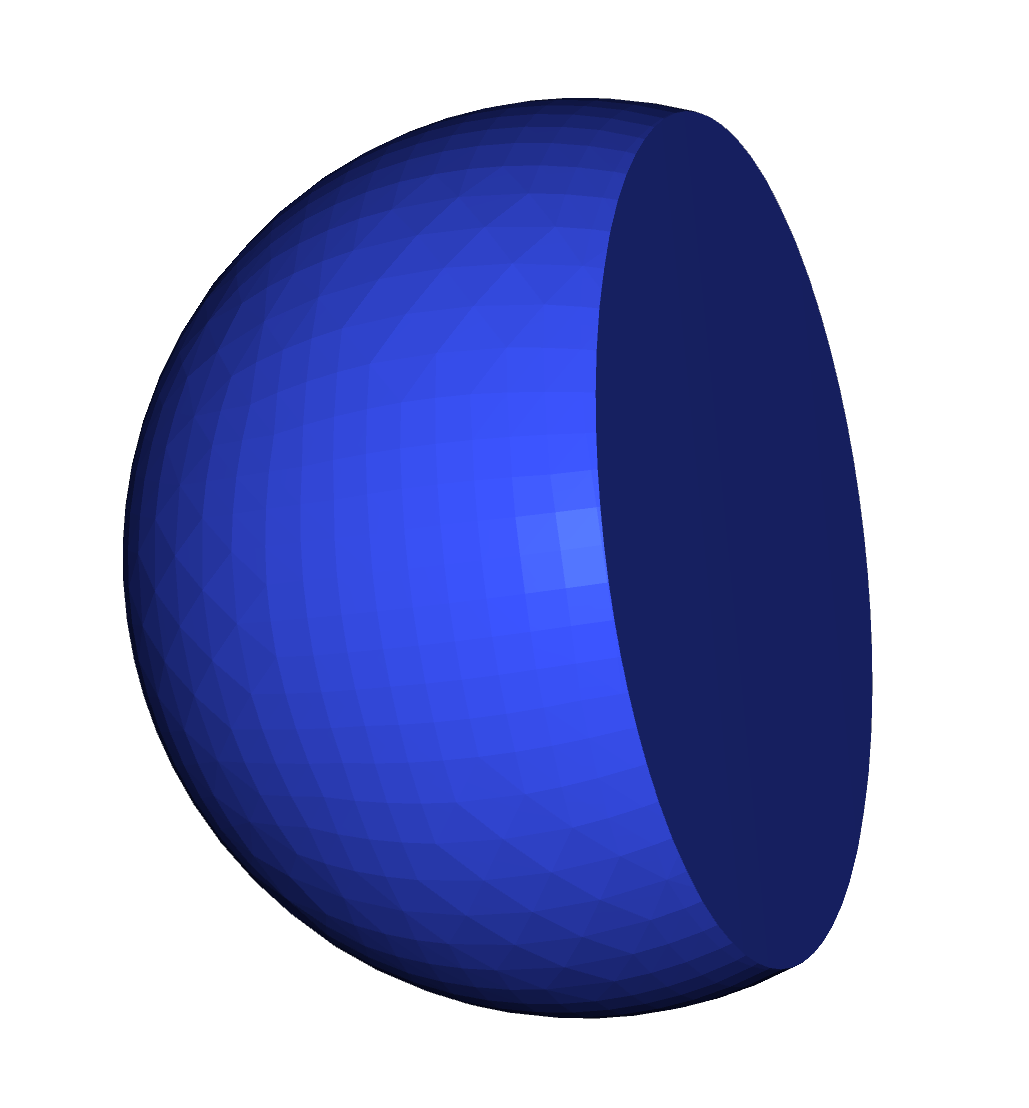

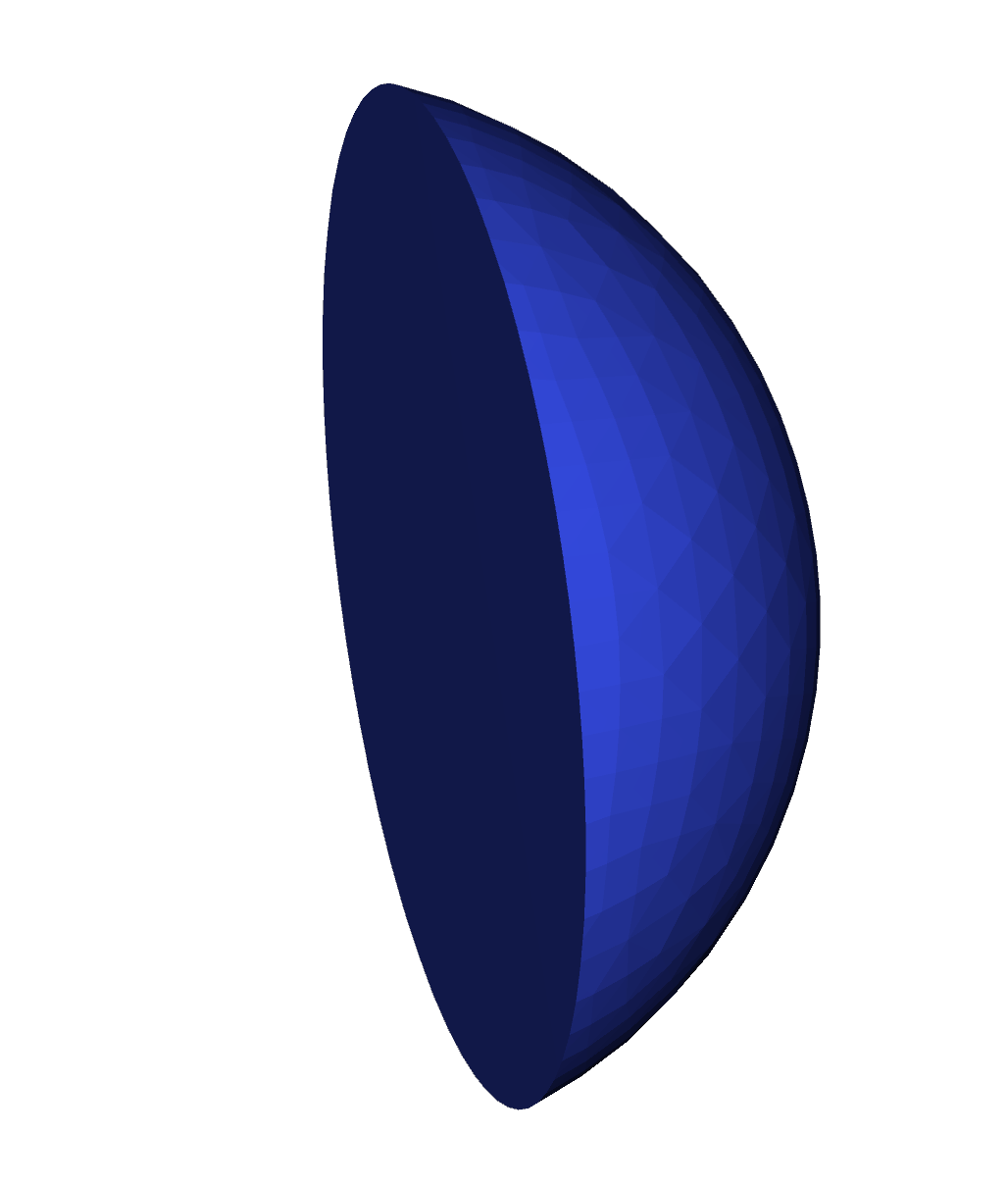

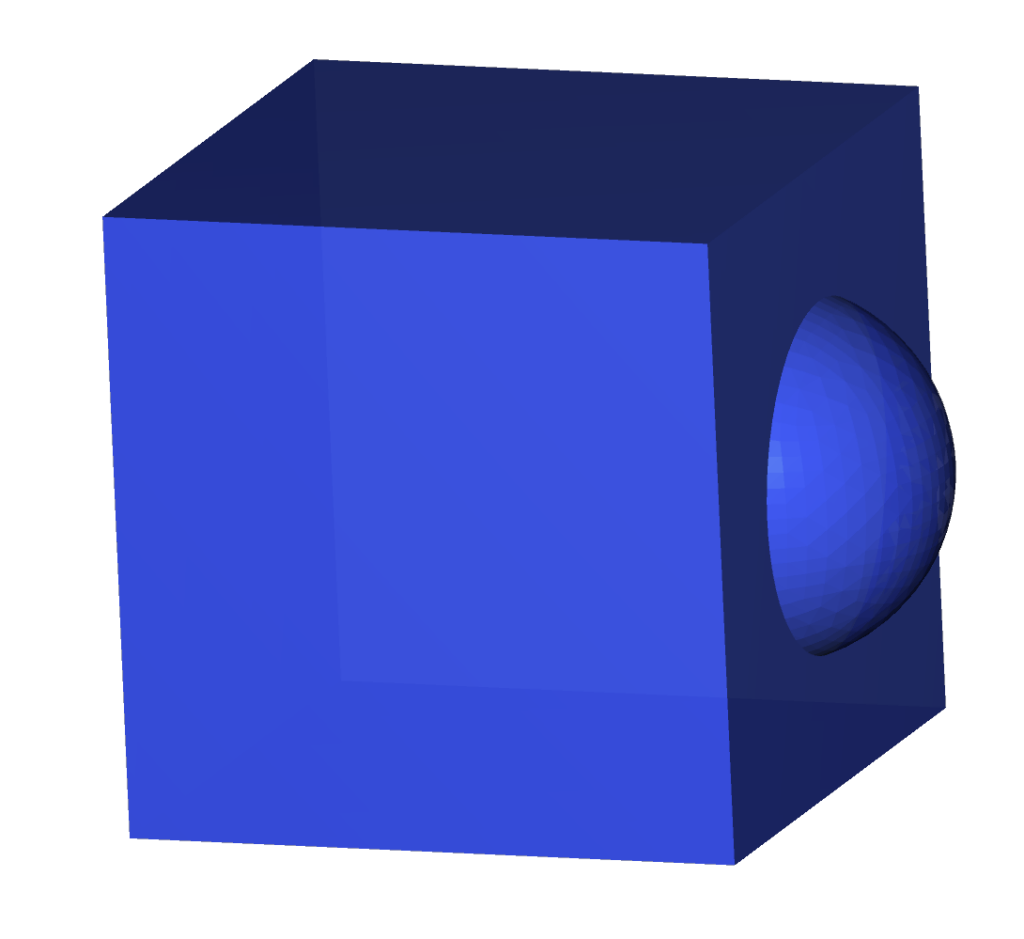

The main 3D boolean operations, fundamental in 3D boolean library, include:

MeshLib leads in 3D processing, offering advanced 3D boolean operations, known for their speed and precision. As an open-source 3D geometry library, it supports both C++ and Python, offering versatility and easy integration into various projects. MeshLib’s recognition as the fastest tool for 3D boolean operations on the market accelerates project timelines, while its accuracy ensures the highest quality of 3D models. Besides MeshLib is based on robust algorithms and calculations you may learn more about here link. This combination of features makes MeshLib an essential resource for anyone looking to develop undertake sophisticated 3D modeling and application development.

"With MeshInspector MeshLib we were able to automate many of our workflow processes, thanks to its advanced, modern, and efficient dental and geometry oriented algorithms, covering many of our orthodontic-related tasks: CT and intraoral scan segmentation, voxel and Boolean operations, editing, aligning, visualization, inspection, and import/export of mesh objects. We use the versatile MeshInspector MeshLib API, both in production and R&D for fast prototyping and testing of our ideas."

Over the past year, MeshLib has transformed my approach to design and analysis in landscape architecture and architecture projects. This powerful library excels in critical areas, such as geometry processing, interactive booleans, point cloud manipulation, and curve offsetting. These features enhance design workflows, allowing for dynamic modifications, efficient terrain modeling, stormwater flow analysis, and advanced wind flow visualiiza....."